-

CN

0755 - 8409 1669

0755 - 8409 1669

0755 - 8409 1669

0755 - 8409 1669

Release Time:2025-05-10 Click Count:0

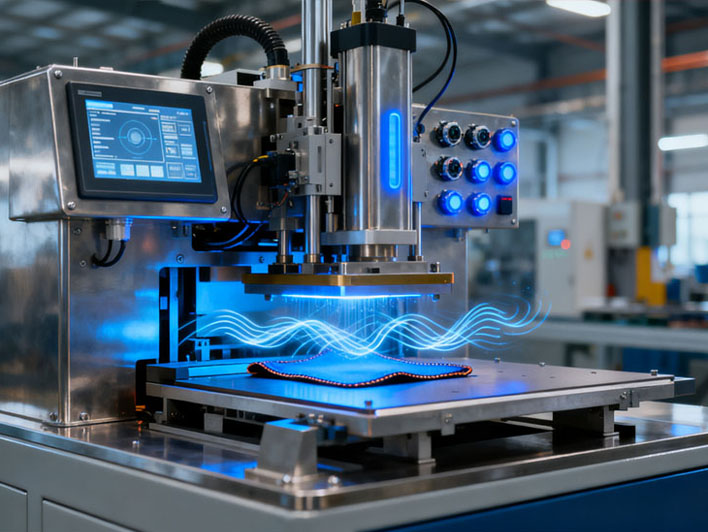

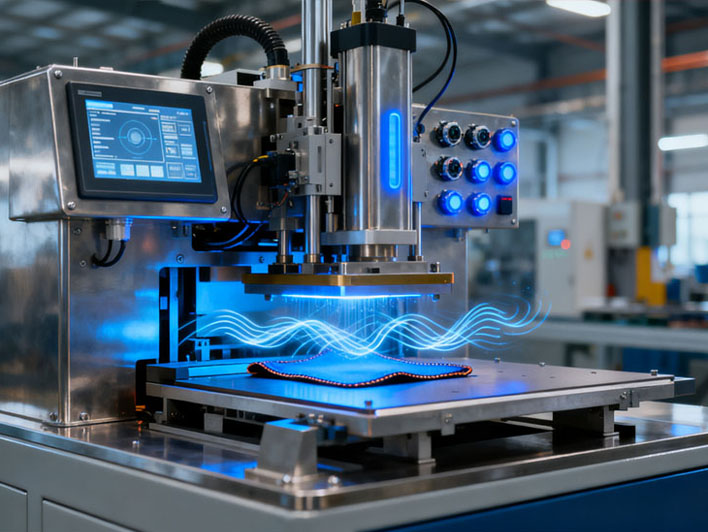

The working principle of high-frequency machine:

High frequency current flows through a heating coil that is wound into a ring or other shape, generating a strong magnetic beam that changes instantaneously inside the coil. Then, the magnetic beam is passed through a mold to the surface of the plastic medium that needs to be processed. In the opposite direction of the medium and the heating current, a corresponding strong eddy current is generated. Due to the resistance of plastic media, a lot of Joule heat is generated, causing the temperature of the plastic media to rise rapidly. Using molds for high-frequency shaping can achieve the purpose of imprinting or heat sealing the surface of the media.

Characteristics of high-frequency machine:

The high-frequency frequency mainly adopts the international industrial band of 27.12MHz, which complies with international standards. High frequency adopts a self-developed system to avoid electromagnetic wave radiation interference, greatly reducing the direct radiation intensity of high-frequency electromagnetic waves on the human body. High frequency can be equipped with a stepless heating device according to the characteristics of the plastic and plastic products that need to be heat sealed and welded. The temperature can be adjusted according to the properties of the material, mainly for heating the surface of the mold. The high-frequency electronic tube adopts the latest developed self flowing protection device system, which mainly serves to protect the high-frequency electronic tube from unnecessary tube burnout caused by excessive current. The high-frequency mold adopts the latest American technology anti ignition device system, mainly using the NL5557 high-sensitivity spark device, which can instantly protect the high-frequency mold from burning out due to excessive current.

Scope of application of high-frequency machine:

The high-frequency machine is mainly suitable for the heat sealing, welding, sealing, and fusion of PVC and materials containing more than 10% PVC | TPU | PU | EVA | PET | PETG:

① Shoe, hat, and clothing signs: shoe upper embossing, sole welding, insole embossing, insole welding, hat embossing, soft film embossing;

② Accessories, toys, stationery: crafts welding, accessories welding, gift packaging, toy welding, toy packaging, toy welding, toy embossing;

③ Leather goods and bags: leather welding, leather embossing, leather welding, leather welding, bag embossing, towel embossing, genuine leather embossing;

④ Door mats, floor mats, and carpets: door mat embossing, door mat welding, plastic door mat embossing, carpet embossing, floor mat welding, floor mat embossing;

⑤ Plastic packaging sealing: plastic welding, PVC packaging bag welding sealing, plastic welding, PVC packaging bag, hot water bag, electrical vacuum packaging;

⑥ Medical supplies and equipment: disposable PVC packaging bags, catheterization bags, catheterization bags, extracorporeal drainage bags, emergency stretchers, oxygen masks;

⑦ Automotive interior supplies: PVC packaging bags, car door panels, steering wheel covers, anti lattice welding, reflective sticker welding, reflective film welding;

⑧ Welding other types: tent welding fusion, canvas welding film structure welding, soft film ceiling welding, PVC packaging bag skirt welding.

2025-05-10

2025-05-10

2025-05-10

2025-05-10

2025-05-15