-

CN

0755 - 8409 1669

0755 - 8409 1669

0755 - 8409 1669

0755 - 8409 1669

Release Time:2025-05-15 Click Count:0

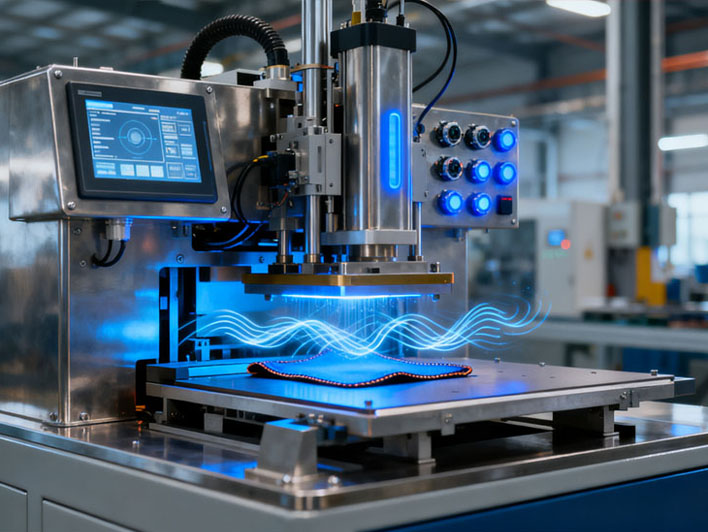

As a packaging equipment, the high-frequency vacuum forming packaging machine is highly favored by manufacturers and consumers due to its ability to weld materials while the production industry enters a transformation period. After sealing, the products inside the high-frequency packaging are transparent and easy to see The high-frequency vacuum forming packaging machine can also be used for plastic welding, PVC welding, plastic welding, genuine leather stamping, and other applications. With the continuous development of the plastic industry, it is driving the development of the high-frequency industry. The application of high-frequency vacuum forming packaging machines in the plastic industry is excellent and has become one of the most popular packaging equipment on the market.

The high-frequency vacuum packaging machinery industry may see the following four new technological developments:

1、 Compatibility of high-frequency vacuum forming packaging machine

Focusing solely on host production without considering the completeness of supporting equipment will result in the packaging machinery not being able to perform its intended functions. Therefore, developing supporting equipment to maximize the expansion of the host's functions is a crucial factor in improving the market competitiveness and economy of the equipment. Germany pays attention to the completeness of complete sets when providing production automation lines or assembly line equipment to users. Whether it is high-tech added value or relatively simple equipment categories, they are provided according to the requirements of compatibility.

2、 Efficiency of high-frequency vacuum forming packaging machine

High frequency vacuum packaging machinery manufacturers are increasingly focusing on developing fast and low-cost packaging equipment. The future development trend is for equipment to be smaller, more flexible, versatile, and efficient. This trend also includes saving time and reducing costs, so the packaging industry is pursuing modular, concise, and movable packaging equipment. In the field of packaging machinery automation, automated operating programs have been widely used, such as PLC equipment, data collection systems, etc.

3、 Simplicity of high-frequency vacuum forming packaging machine

In the future, packaging machinery must have multiple functions and simple adjustment operations, and computer-based intelligent instruments will become a new trend in food packaging controllers. OEM manufacturers and end consumers will tend to purchase packaging machinery that is easy to operate and install, especially with the current large-scale layoffs in the manufacturing industry, the demand for simple operating systems will increase day by day. Structural motion control is crucial to the performance of packaging machinery and can be achieved through high-precision controllers such as motors, encoders, digital control (NC), and power load control (PLC). Therefore, in order to gain a foothold in the future packaging market, efficient customer service and mechanical maintenance will be one of the most important competitive conditions.

2025-05-10

2025-05-10

2025-05-10

2025-05-10

2025-05-10