-

CN

0755 - 8409 1669

0755 - 8409 1669

0755 - 8409 1669

0755 - 8409 1669

As a packaging equipment, the high-frequency vacuum forming packaging machine is highly favored by manufacturers and consumers due to its ability to weld materials while the production industry enters a transformation period. After sealing, the products inside the high-frequency packaging are transparent and easy to see The high-frequency vacuum forming packaging machine can also be used for plastic welding, PVC welding, plastic welding, genuine leather stamping, and other applications. With the continuous development of the plastic industry, it is driving the development of the high-frequency industry. The application of high-frequency vacuum forming packaging machines in the plastic industry is excellent and has become one of the most popular packaging equipment on the market.

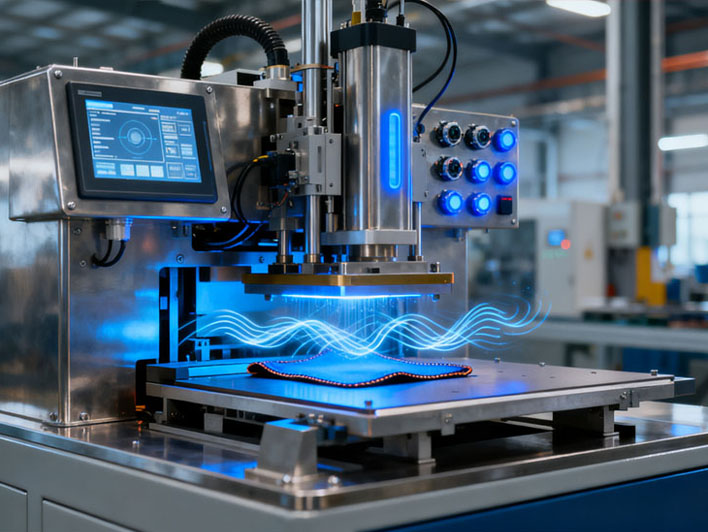

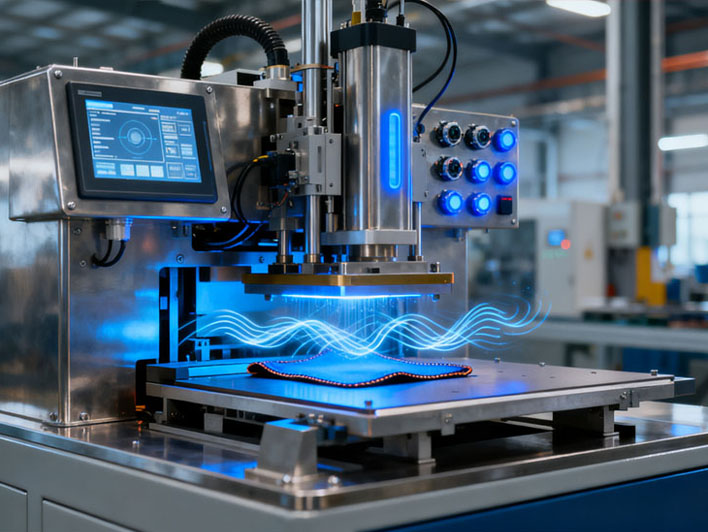

The basic principle of an automatic high-frequency machine is to use a high-frequency electric field to generate heat energy by causing molecules in plastic to move at high speed, and to fuse various products together. The electromagnetic field generated by the oscillation of high-voltage rectification self-excited electronic tubes instantly changes plastic molecules, achieving effects such as welding, cutting, sealing, and embedding under the action of aerodynamic external forces and molds. Easy to operate and learn, high efficiency, suitable for welding and cutting large plastic products, with simpler processes and better results. Therefore, high-frequency machines are increasingly widely used in various industries.

The motor power of the automatic high-frequency machine equipment should be greater than the power required for stamping. The automatic high-frequency machine equipment should ensure convenience and safety in use. Large tonnage double column or four column automatic high-frequency machine equipment should be selected for the leveling and shaping molds of the cadres.

How to detect if the current is normal when the above phenomenon occurs?1. Observe whether the electronic tube lights up on the homepage and use high-frequency fuses;

High frequency plastic welding machine is a device that uses high-frequency dielectric heating technology in the field of plastic packaging. It uses an electronic self-excited oscillator to generate a high-frequency electric field, which is applied to the electrode. Under the action of the high-frequency electric field, the molecular structure of the plastic polarizes and generates heat, achieving the purpose of hot melting under pressure. Why is it necessary to have a melting mold to match the high-frequency synchronous melting machine

High frequency current flows through a heating coil that is wound into a ring or other shape, generating a strong magnetic beam that changes instantaneously inside the coil. Then, the magnetic beam is passed through a mold to the surface of the plastic medium that needs to be processed. In the opposite direction of the medium and the heating current, a corresponding strong eddy current is generated. Due to the resistance of plastic media, a lot of Joule heat is generated, causing the temperature of the plastic media to rise rapidly. Using molds for high-frequency shaping can achieve the purpose of imprinting or heat sealing the surface of the media.